Difference between dtf and sublimation printing

DTF (Direct to Film) prints directly onto a film, which is then transferred to the desired material. Sublimation, one of the printing techniques, uses heat to sublimate a design from sublimation paper onto another surface, such as fabrics or sheets. With decades of combined expertise in the printing industry, we’re here to guide you through the nuances of each method, including sublimation printers, dtf printers, sublimation paper, and sublimation ink.

Let’s unpack this:

🔍 DTF (Direct to Film) Printing:

- Picture a two-stage process. Initially, designs are printed onto a sheet of fabric using advanced dtf printing technology. Following this, a heat application transfers the design onto various fabric materials, from tees to totes. The design is then imprinted onto the fabric products, creating a visually appealing sheet image.

- Its strength? DTF doesn’t play favorites. Whether it’s dark or light fabric made of cotton or polyester, our products are up for the task. We use an advanced image printing method to ensure high-quality results.

🔍 Sublimation Printing:

- Envision this: A design imprinted on a unique paper. Introduce heat to fabric, and the design seamlessly integrates with another material, often polyester. This process is commonly used in DTF printing to create high-quality products and achieve vibrant image results.

- A word of caution: Sublimation has preferences. It’s most compatible with light-colored materials, making dark designs a bit of a challenge.

Expert Tip: For businesses and individuals alike, the choice between DTF and Sublimation print isn’t black and white. When it comes to printing products on fabric, it’s important to consider which method will produce the best image. It’s a strategic decision, influenced by your specific needs, desired output, budget, and the type of image you want to print using dtf printing.

With a wealth of knowledge and experience in print under our belt, we invite you to join us on this enlightening journey. Let’s explore the world of digital printing together and determine which method aligns best with your aspirations.

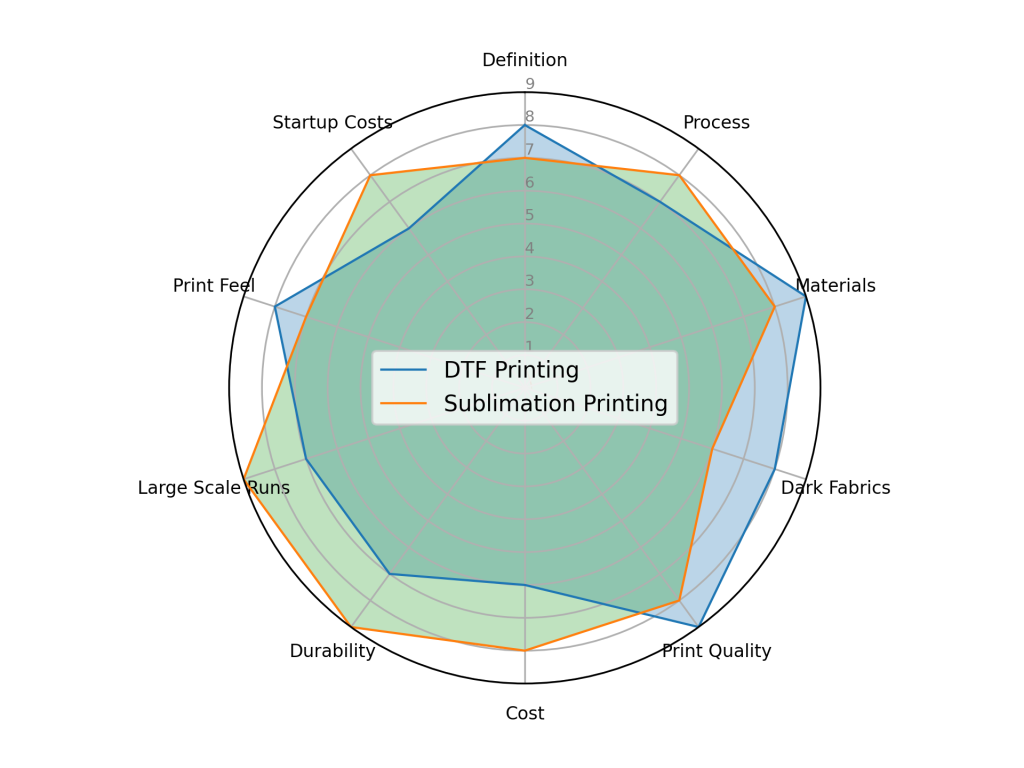

Here’s a table highlighting the key differences between DTF and Sublimation printing:

| Aspect | DTF Printing | Sublimation Printing |

|---|---|---|

| Definition | Digital method that prints directly onto a film. | Uses heat to transfer designs from a special paper to the substrate. |

| Process | Two-step process involving inkjet technology and heat. | Involves transitioning ink from solid to gas state, bonding with the substrate. |

| Best Suited Materials | Cotton, polyester, wood, metal, leather. | Polyester, nylon, acrylic, ceramics, metal, glass. |

| Color on Dark Fabrics | Can print vibrant designs on both light and dark fabrics. | Works best on light-colored materials; struggles with dark fabrics. |

| Print Quality | High-resolution, vibrant prints. | Long-lasting colors, seamlessly integrated into the substrate. |

| Cost | Higher initial costs, especially for equipment. | More budget-friendly, especially for startups. |

| Durability of Design | Might be prone to cracking or peeling over time. | Designs won’t fade, crack, or peel due to chemical bonding with the substrate. |

| Suitability for Large Scale Runs | Best for small to medium print runs. | Ideal for larger print runs. |

| Print Feel | Design feels slightly thicker due to adhesive used. | Smooth texture as the design is chemically bonded and integrated into the fabric. |

| Startup Costs | Requires DTF printer, curing oven, PET sheets, adhesive powder. | Requires sublimation printer, special ink, and paper. |

What Is DTF Printing ?

In the ever-evolving world of digital printing, DTF (Direct to Film) printing has emerged as a game-changer. But what exactly is it, and why is it gaining so much traction? Let’s dive into the basics.

Definition and Process of DTF Printing

DTF, or Direct to Film, is a modern digital printing technique that, as the name suggests, involves printing directly onto a film. Here’s a simplified breakdown of the process:

- Design Creation: First and foremost, a design is crafted digitally using graphic design software.

- Printing on Film: Using specialized inkjet printers, this design is then printed onto a transparent PET film. These printers typically use CMYK inks along with white ink to ensure vibrant and detailed prints.

- Applying Adhesive Powder: Once printed, the design on the film is coated with a layer of adhesive powder. This powder will later help the design bond with the material it’s being transferred to.

- Heat Transfer: The film, now coated with adhesive, is placed onto the desired material (be it a t-shirt, hoodie, or any other fabric). Using a heat press, the design is transfer the image from the film to the material. The heat melts the adhesive, ensuring the design sticks firmly.

- Final Cure: To ensure durability and longevity, the printed material undergoes a final curing process, usually with a conveyor dryer or heat press.

Key Advantages of DTF Over Other Methods

Versatility in Material Choice: Unlike some printing methods that are picky about fabric types, DTF is versatile. Whether it’s cotton, polyester, or a blend, DTF has got you covered.

Vibrant Prints on Dark Materials: Ever struggled with getting bright designs on dark fabrics? With DTF, that’s a worry of the past. Thanks to the white ink used in the process, designs pop, even on darker materials.

Soft Feel: Nobody likes a print that feels like a chunk of plastic. DTF prints are known for their soft touch, making the printed apparel comfortable to wear.

Durability: With the right care, DTF prints can withstand the test of time, resisting fading, cracking, or peeling.

Eco-friendly Inks: Many DTF printers use water-based inks, which are not only safer for the environment but also for the end-users.

What Is Sublimation Printing?

Sublimation printing, often hailed as a revolutionary method in the world of digital printing, has transformed the way we imprint designs onto various materials. But what sets it apart? Let’s delve into the essentials.

Definition and Process of Sublimation Printing

Sublimation Printing is a unique digital printing method that involves transferring designs from paper to a chosen material using heat. The magic lies in the ink’s ability to transition from a solid to a gas, bypassing the liquid phase. Here’s a step-by-step breakdown:

- Design Creation: Initially, a digital design is crafted using graphic design software tailored to the desired output.

- Printing on Special Paper: The design is printed onto a specific sublimation transfer paper using sublimation inks.

- Heat Transfer: The printed paper is then placed onto the desired material, be it fabric, ceramic, or metal. Using a heat press, the design is transferred. Under the influence of heat, the sublimation ink vaporizes and permeates the material, settling into its fibers or pores.

- Cooling and Setting: Once the heat is removed, the ink solidifies within the material, ensuring the design is permanent and won’t easily fade or wash out.

Key Advantages of Sublimation Over Other Methods

Seamless Integration: Unlike other methods where the design sits on top of the material, sublimation embeds the design within. This results in a smooth, seamless finish.

Vivid and Detailed Designs: Sublimation printing is known for producing bright, vibrant, and highly detailed prints, making it ideal for intricate designs and photographs.

Long-lasting Prints: Since the ink integrates into the material, sublimation prints are resistant to fading, even after multiple washes.

Broad Material Compatibility: From apparel and mugs to phone cases and flags, sublimation is versatile and compatible with a wide range of materials, especially those with a high polyester content.

Eco-friendly: Sublimation printing is a green process. The inks are water-based, and there’s minimal waste, making it an environmentally friendly choice.

Quick Turnaround: Ideal for businesses, sublimation printing often offers a faster turnaround compared to other methods, especially for custom orders.

In essence, sublimation printing stands out for its ability to produce vibrant, durable, and detailed prints across a myriad of materials, making it a favorite in the realm of digital printing.

Difference between DFT Printing vs. Sublimation Printing

In the vast landscape of digital printing, DTF and Sublimation are two prominent contenders. But how do they stack up against each other? Let’s dive into a direct comparison to help you make an informed decision.

Materials Required for Each Method

DTF:

- Specialized DTF inkjet printers.

- Transparent PET film.

- Adhesive powder.

- Heat press or conveyor dryer.

Sublimation:

- Sublimation inks.

- Sublimation transfer paper.

- Heat press.

- Optional: specialized sublimation printer or converted inkjet printer.

Startup Costs and Investment Considerations

DTF:

- DTF printers can start from $3,000.

- Additional costs include adhesive powder, PET sheets, and inks.

- A curing oven or heat press is also a necessary investment.

Sublimation:

- Entry-level sublimation printers range from $400-$500.

- Converting an existing inkjet printer can be more cost-effective.

- Sublimation inks and papers are recurring costs.

Print Quality and Visual Appeal

DTF:

- Offers vibrant, high-resolution prints.

- Capable of printing on both light and dark materials with equal clarity.

Sublimation:

- Produces bright and detailed designs, especially on light-colored substrates.

- Designs are seamlessly integrated into the material, ensuring a smooth finish.

Printing Process and Ease of Use

DTF:

- Involves multiple steps, including printing, adhesive application, heat transfer, and curing.

- Can be time-consuming and requires careful attention to detail.

Sublimation:

- Simpler process with fewer steps.

- Design is printed on paper and then transferred using heat.

Suitable Materials and Substrates

DTF:

- Versatile with compatibility across various materials, including cotton, polyester, metal, wood, and leather.

Sublimation:

- Best suited for polyester and synthetic materials.

- Can also be used on ceramics, metals, and certain plastics.

Design Longevity and Durability

DTF:

- Designs are durable but may crack or peel over time with wear and tear.

- Proper care can extend the life of the print.

Sublimation:

- Designs are chemically bonded to the material, ensuring they don’t fade, crack, or peel easily.

- Extremely durable and resistant to multiple washes.

DTF printing and sublimation printing Limitations and Challenges

In the realm of digital printing, both Sublimation and DTF offer incredible advantages. However, like all technologies, they come with their own set of challenges. Let’s delve into the limitations and hurdles associated with each method.

Sublimation

- Dark Fabric Dilemma: One of the most significant challenges with sublimation printing is its limitation with dark fabrics. The process works best on light-colored materials, and when used on dark fabrics, the vibrancy and clarity of the design can be compromised.

- Substrate Compatibility: Sublimation requires specific substrates to work effectively. It’s best suited for polyester and synthetic materials. While it can be used on ceramics, metals, and certain plastics, it’s not compatible with 100% cotton materials. This can be limiting for businesses or individuals looking to print on a diverse range of materials.

- White Color Limitation: Sublimation printing doesn’t produce the color white. Any white in a design will simply be left unprinted, taking on the color of the substrate. This can be a challenge when trying to reproduce designs with white elements.

DTF (Direct to Film)

- Higher Initial Investment: DTF printing requires a more substantial upfront investment. The specialized DTF printers can start from $3,000, and that’s before considering the costs of adhesive powders, PET sheets, and inks.

- Maintenance Requirements: DTF printers, given their complexity, demand regular maintenance to ensure they function optimally. This not only involves time but can also add to operational costs.

- Multi-step Process: The DTF printing process, while producing stunning results, is multi-faceted. It involves printing, adhesive application, heat transfer, and curing. Each step must be executed with precision, making it more time-consuming and potentially more prone to errors compared to simpler methods.

- Thickness of Prints: Due to the adhesive used in the DTF process, the prints can sometimes feel thicker on the material. While this might not be an issue for some applications, it might not be ideal for those seeking a super-soft, seamless feel to their printed items.

Conclusion : difference between sublimation printer and dtf printer

The world of digital printing is vast and varied, offering a plethora of options for businesses and individuals alike. As we’ve delved into the intricacies of DTF and Sublimation printing, it’s evident that both methods come with their unique set of advantages and challenges.

Recap of Key Differences and Similarities:

- DTF (Direct to Film) Printing:

- Uses a direct printing method onto a film, followed by a heat transfer process.

- Suitable for a wide range of materials, including cotton, polyester, and even non-fabric substrates like wood and metal.

- Offers vibrant, high-resolution prints, especially beneficial for intricate designs.

- Can be more cost-intensive, especially for startups.

- Sublimation Printing:

- Involves transferring designs from special ink-absorbent paper to the substrate using heat.

- Best suited for polyester and other synthetic materials.

- Produces long-lasting designs that are chemically bonded to the substrate, ensuring durability.

- Works best on light-colored materials and might not produce the color white.

While both methods are digital and use heat as a part of their process, their applications, costs, and results can vary, making it crucial for businesses and individuals to understand these nuances.

Recommendations for Businesses and Individuals:

- Assess Your Needs: Before diving into either method, it’s essential to evaluate your specific requirements. Are you looking to print on a diverse range of materials, or is your focus primarily on fabrics like polyester?

- Budget Considerations: While sublimation might be more budget-friendly, especially for those just starting out, DTF can offer a broader range of applications, albeit at a higher initial cost.

- Quality vs. Quantity: If you’re aiming for small-scale, high-quality prints, DTF might be your go-to. However, for larger runs, especially on light-colored materials, sublimation could offer better value.

- Stay Updated: The world of digital printing is ever-evolving. Stay abreast of the latest advancements to ensure you’re making the most informed decisions for your business or personal projects.

- Experiment and Innovate: Don’t be afraid to experiment. Sometimes, the best results come from thinking outside the box and trying something new.

In wrapping up, whether you’re a business aiming to make a mark in the industry or an individual passionate about custom prints, understanding the strengths and limitations of dtf vs sublimation printing is crucial. By weighing the pros and cons and aligning them with your specific needs, you can harness the power of digital printing to its fullest potential.

Check Related post Difference Between Outbox and Sent