What is difference Between Incineration and Pyrolysis in Waste Management

Key Difference – Incineration vs Pyrolysis

Pyrolysis and incineration are both processes that use heat to break down waste. Incineration combusts waste directly with oxygen to destroy waste and recover energy. Pyrolysis thermally decomposes waste without oxygen to produce oils, gases and biochar that can be further refined and utilized. Both technologies have roles in waste management depending on desired outcomes.

Waste management is a major concern worldwide as populations grow and consumption rises. Finding ways to safely and sustainably treat and dispose of waste is crucial.

Two thermochemical waste treatment methods are often compare when examining technology options.

But what exactly is the difference between them? This article will examine the key distinctions.

Here is a comparison table of difference between incineration and pyrolysis:

| Feature | Incineration | Pyrolysis |

|---|---|---|

| Definition | The combustion of organic matter in the presence of oxygen | The thermal decomposition of organic matter in the absence of oxygen |

| Temperature | 800-1,200°C | 300-600°C |

| Oxygen requirement | Required | Not required |

| Products | Ash, gases | Gaseous components, liquid and solid residues |

| Energy efficiency | Low | High |

| Emissions | Dioxins, furans, heavy metals | Fewer emissions |

| Suitability for waste | Municipal solid waste, hazardous waste | Biomass, plastics, rubber |

| Cost | Low | High |

| Maturity | Mature technology | Emerging technology |

What is Pyrolysis?

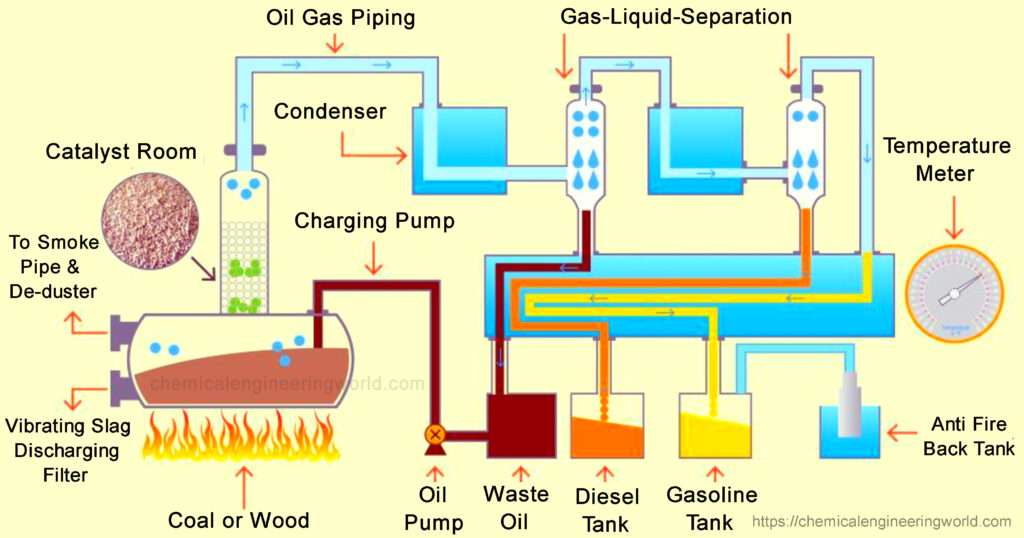

Pyrolysis refers to the thermochemical decomposition of organic material at high temperatures in the absence of oxygen. The pyrolysis plant converts waste biomass into liquid oils, solid char and syngas by heating the feedstock to typically 450-800°C in an oxygen free environment.

It can process:

- Biomass

- Plastic waste

- Tire waste

Key things to understand :

- It is an endothermic process, meaning it requires energy input in the form of heat.

- It can accept a wide variety of organic waste feedstocks like wood, agricultural residues, waste plastics, scrap tires, and municipal solid waste.

- The main products are bio-oil, syngas, and biochar. The product yields can be optimize based on the operating temperature, pressure, residence time and other parameters.

- Bio-oil and syngas can be refine into value-added fuels and chemicals. Biochar can be use as a soil amendment or converted into activated carbon. This enables resource and energy recovery.

- Since no oxygen is present during the thermal decomposition process, pyrolysis does not combust the feedstock into ash and flue gases like incineration.

- Pyrolysis systems can be designe to operate with low emissions and environmental impact.

- Pyrolysis technologies include slow, fast, flash, microwave, vacuum, and other types, each with different characteristics.

Advantages

- Significant waste reduction

- The potential for energy recovery

- Destruction of harmful waste, reducing the risk of contamination

Disadvantages

- Potential for carbon emissions

- High energy consumption

- Possible generation of harmful byproducts

So in summary, pyrolysis provides an alternative to incineration that can convert organic wastes into useful energy products and chemicals while reducing emissions. This makes it attractive for managing waste streams like plastics, tires, agricultural residues, forestry waste, and more. The liquids and gases produced can also be used to generate electricity.

What is Incineration?

Incineration is a waste treatment process that involves the combustion of organic material such as municipal solid waste or hazardous waste. It uses high temperatures, typically above 850°C, to convert waste materials into ash, flue gas, and heat.

This process is commonly use for:

- Municipal solid waste

- Hazardous waste

- Chemical waste

Key things to understand :

- It is an exothermic process, meaning it generates excess heat that can be recovered to produce steam and electricity. This makes waste-to-energy via incineration attractive.

- Typical waste streams treated by incineration include municipal solid waste, medical waste, hazardous waste, sewage sludge, and more.

- It reduces the volume and weight of waste by over 70%. The remaining ash requires disposal in landfills. Toxic flue gases require treatment before release.

- Incinerators require auxiliary fuel to sustain the combustion reactions. Natural gas, fuel oil, or waste gases can supplement the heating value of waste.

- Advanced incinerators utilize pollution control systems to limit emissions of particulates, acids, heavy metals, and dioxins that can result from poor combustion.

- Energy recovered from incinerators can be used for district heating or converted into electricity.

- It destroys waste rather than recovering resources. Critics point to the potential loss of recyclable/recoverable materials and risk of harmful emissions.

Advantages

- Significant waste reduction

- The potential for energy recovery

- Destruction of harmful waste, reducing the risk of contamination

Ddisadvantages

- Potential for carbon emissions

- High energy consumption

- Possible generation of harmful byproducts

In summary, It provides volume reduction and energy recovery from waste, but also has pollution concerns and reduces potential for material recycling. Waste management plans often utilize incineration for residuals after recycling.

Differences Between Pyrolysis and Incineration

Now that we’ve outlined the basics of pyrolysis and incineration, let’s examine some of the key differences between these two thermal waste treatment methods:

- Presence of Oxygen – The primary difference is that incineration uses excess air/oxygen to combust waste whereas pyrolysis thermally decomposes waste in the absence of oxygen.

- Energy Balance – Incineration is an exothermic process that generates excess heat energy. Pyrolysis requires the input of heat energy to drive the thermal decomposition reactions.

- Process Products – Incineration reduces waste to bottom ash and flue gases which require treatment/disposal. Pyrolysis produces liquid oils, syngas, and biochar which can be further refined and utilized.

- Emissions – Incineration can produce pollutants like dioxins, furans, nitrogen oxides, sulfur oxides, particulates, and heavy metals if combustion is incomplete. Pyrolysis produces a fraction of the emissions.

- Adaptability – Pyrolysis can process a wide array of organic waste feedstocks. Incineration typically requires pretreatment and a consistent stream of high calorific waste.

- Resource Recovery – Pyrolysis enables the recovery of chemical feedstocks and fuels. Incineration destroys waste materials with some energy recovery.

- Capital Costs – Pyrolysis systems have high upfront capital costs for construction. Incinerators are cheaper to construct but have high ongoing operating costs.

In summary, pyrolysis provides an oxygen-free thermochemical conversion process that generates usable byproducts while minimizing emissions, whereas incineration uses combustion to destroy waste and recover energy. Waste managers can utilize both solutions as part of an integrated plan.

Applications of Pyrolysis and Incineration in Waste Management

Both pyrolysis and incineration offer utilities for converting different waste streams with energy/resource recovery and volume reduction. Here are some examples of how these technologies can be applied:

- Incineration works well for treating consistent streams of municipal solid waste, hazardous waste, and medical waste after recycling. It provides significant volume reduction and waste-to-energy capabilities.

- Pyrolysis enables the conversion of scrap tires, plastic waste, agricultural residues, forestry/timber waste into liquid biofuels, chemical feedstocks, and biochar. This provides resource recovery.

- Sewage sludge can be dried and pyrolyzed into bio-oil, syngas, and biochar, providing an alternative to incineration or landfilling.

- MSW with high moisture and low calorific value can be dried then pyrolyzed to increase energy yields compared to direct incineration.

- Hazardous waste may first require incineration to destroy harmful organics before metals recovery from the ash. Pyrolysis alone may not treat all hazardous waste safely.

- Fast pyrolysis maximizes bio-oil yields from wood waste, agricultural residues and organic MSW, while slow pyrolysis optimizes biochar.

The unique characteristics of different waste streams and desired outcomes will inform optimal solutions. An integrated plan using recycling, pyrolysis, incineration and anaerobic digestion can provide the most value. Policy, incentives and economics also factor into adoption.

Conclusion and Key Takeaways

In summary, pyrolysis and incineration both provide thermochemical conversion solutions for waste management but have key differences in their processes and outcomes.

The main takeaways around pyrolysis vs incineration include:

- Pyrolysis decomposes waste in the absence of oxygen into various fuels and chemicals that can be utilized, while incineration uses combustion in excess oxygen to destroy waste and produce heat energy.

- Incineration requires waste with sufficient calorific value and consistency in composition for proper combustion and energy recovery.

- Pyrolysis can process a wide array of waste feedstocks into useful bio-oil, syngas and biochar, but has high capital costs.

- Incineration reduces volume but can have harmful emissions if combustion is incomplete, whereas pyrolysis is a cleaner thermochemical process.

- Both technologies provide waste reduction and treatment capabilities that can be applied based on the waste stream characteristics, desired outcomes, and overall waste management strategy.

Sustainable waste management requires utilizing the appropriate solutions for the given context. Pyrolysis and incineration each have roles to play as alternatives to landfilling that reduce waste volumes and recover value from what is disposed. Carefully evaluating the merits of these thermal waste treatment options allows planners to develop integrated systems that safely and cost-effectively manage different waste streams while recovering resources and energy.